🧭 Introduction: Why Traceability of Medical Devices Is More Important Than Ever

Medical device traceability is a global system that strengthens patient safety, streamlines supply chains, and builds trust with regulators, healthcare providers, and patients alike.

Through single identification and traceability of each device across its entire lifecycle, medical device traceability allows companies to

✅ Comply with FDA and EU MDR

✅ Efficiently recapturing product recall

✅ Monitor adverse events and optimize patient outcomes

✅ Have transparency of global supply chains

🚦 What Is Medical Device Traceability?

It is a function that tracks and traces a medical device from the site of initial manufacture to the site of patient or healthcare provider use.

It involves the allocation of unique identification codes for the devices (usually through UDI systems), tracking, and registration of device data onto national or international databases.

Medical device traceability facilitates:

- Identification of failed or unsafe devices

- Prompt corrective action, such as recalls

- Monitoring and post-market surveillance

- Supply chain integrity and responsibility

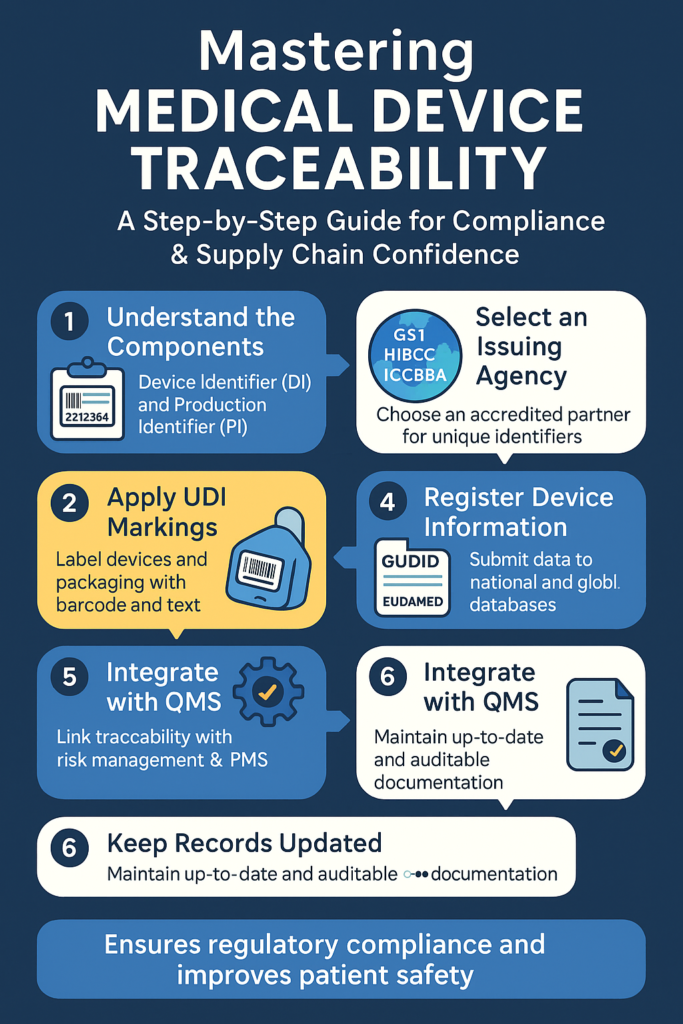

✅ Step-by-Step Guide to Achieving Medical Device Traceability

✅ 1️⃣ Understand the Components of Medical Device Traceability

📌 Device Identifier (DI)

The device identifier (DI) is a permanent component of the unique device.

- It serves to identify the model and manufacturer of the device.

📌 Production Identifier (PI)

The dynamic part, which indicates production-specific information such as

- Serial number

- Lot/batch number

- Manufacturing date

- Expiration date

Why is it important?

Both PI and DI constitute effective medical device traceability, enabling proper tracing at every point along the way and at every stage during the life of the device.

✅ 2️⃣ Select an Accredited UDI Issuing Agency

In aid of global medical device traceability, your identifiers must be from accredited issuers such as

- GS1

- HIBCC

- ICCBBA

These bodies provide formats that standardize the FDA and EU regulatory requirements.

✅ 3️⃣ Apply UDI Markings to Devices and Packaging

One of the most critical aspects of medical device regulatory traceability is marking each device and packaging prominently and electronically with a UDI.

This includes:

- Human-readable label

- Machine-readable barcodes or DataMatrix codes

Why it matters:

Proper marking allows tracing devices in the hospital, supply chain, and regulatory databases.

✅ 4️⃣ Register Device Information in Regulatory Databases

Regulatory Medical Device Traceability involves registering device information in the following databases:

- FDA GUDID (Global Unique Device Identification Database)

- EU EUDAMED (European Database of Medical Devices)

This encourages transparency and facilitates post-market surveillance.

✅ 5️⃣ Integrate Traceability into Your Quality Management System (QMS)

Medical device traceability needs to be part of your QMS as a direct activity of

- Risk Management (ISO 14971)

- Post-Market Surveillance (PMS)

- Corrective and Preventive Action (CAPA)

This makes traceability a component of your system of conformity, rather than treating it as a separate activity.

✅ 6️⃣ Audit and Review Traceability Records

Since products and rules are changing, medical device traceability needs to be ensured at all times:

- Update device records whenever production changes.

- Keep traceability records clean for audit and inspection.

- Keep database entries current with the latest product status.

⚖️ Comparison of Medical Device Traceability in FDA and EU MDR

Requirement

| Requirement | FDA | EU MDR |

|---|---|---|

| UDI Application | Required on most devices | Required on most devices |

| Database | GUDID | EUDAMED |

| Issuing Agencies | GS1, HIBCC, ICCBBA | Same |

| Direct Marking for Reusables | Yes | Yes |

| Post-Market Updates | Required | Required |

⚠️ Common Pitfalls to Avoid in Medical Device Traceability

❌ UDI code misuse by non-authorized issuing agencies

❌ UDI mark ineffective placement on the device units or packs

❌ Nonregistration in required databases

❌ Products released without modification tracing if the product modification is made

❌ Medical Device Traceability as a standalone compliance activity instead of integrating it into QMS and PMS

✅ Best Practices for Successful Medical Device Traceability

✅ Make your issuing agency decision early in the life of your product

✅ Maintain traceability and labeling processes as a procedure-of-record across your company

✅ Train RA/QA, manufacturing, and supply chain personnel on Medical Device Traceability procedures

✅ Conduct traceability compliance audits internally regularly

✅ Centralize your device records and make them easily retrievable