Introduction: Why World-Class Technical Documentation is Your MedTech Advantage

Your technical documentation is your passport to success, market entry, and patient trust. It tells regulators, business partners, and investors that your medical device is compliant, safe, and effective.

You require it for FDA 510(k), PMA, and quality system audits.

This is required for EU MDR CE marking.

✅ Prepares you for post-market surveillance and design optimization.

✅ Makes your audit ready and inspection ready.

✅ Aligned with your firm’s culture of operational excellence and patient safety culture.

Migrating to Expert in Technical Documentation builds you into a robust MedTech company that expands across the globe with patients protected.

???? What is technical documentation?

Technical documentation (or a technical file or design dossier) is an orderly, living set of documents validating your device’s conformity, safety, and performance.

It includes:

✅ Device specifications and descriptions.

✅ Development and design documentation.

✅ Risk management documentation.

✅ Clinical data and evaluations.

✅ Verification and validation tests.

✅ Labeling and IFUs.

✅ PMS and vigilance processes.

It is like the history of your device, with evidence to back it, and prepared for any regulatory audit.

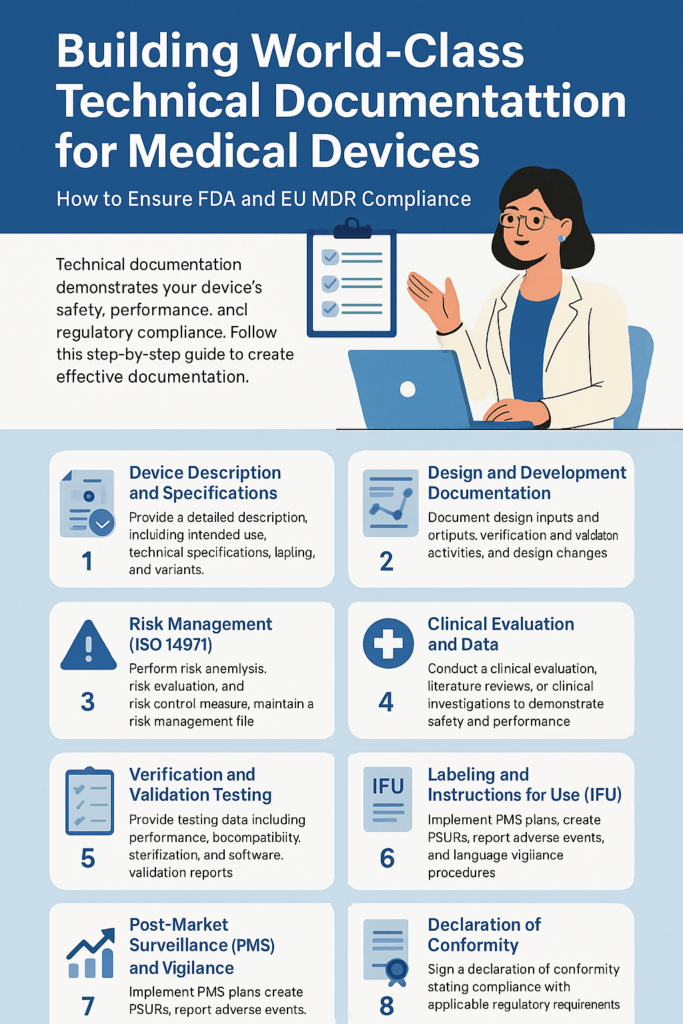

???? Step-by-Step Guide to Creating World-Class Technical Documentation

Below is a step-by-step, actual explanation of what each step entails so that readers can fully grasp what to prepare, why, and how to prepare it correctly.

1️⃣ Device Description and Specifications

✅ What to include:

General Description: Device name, intended purpose, patient population, and use within the clinical environment.

Variants and Accessories: Models, kit configurations, and parts that are not required but available as an option.

Technical Specifications: Materials, size, electronic characteristics, and performance characteristics.

UDI Information: Unique Device Identifier, label configuration, and packaging data.

Manufacturing Overview: List of primary-level manufacturing activities, large vendors, and contract manufacturers.

✅ Why it matters:

Regulators need to understand precisely what your device is, what it does, and how it is used in patient care workflows to evaluate compliance and safety.

✅ Tip in practice: Include plain diagrams and annotated images to make your descriptions visual.

2️⃣ Design and Development Documentation

✅ What to include

Design Inputs: Clinical requirements, user needs, standards to be employed, and regulatory demands.

Design Outputs: Bill of materials, drawings, software levels, and specifications.

Design Verification: Confirmation that output is equal to input (design calculations, bench testing).

Design Validation: Simulated use test, user testing for usability, and clinical validation under actual usage.

Design Change Control: History of why changes occurred, individual authorizing changes, evidence.

This shows that your product was smartly developed and validated based on user needs, safety, and regulatory specifications.

Practice tip: Design a History File (DHF) as your development working document and provide it as part of your Technical File.

3️⃣ Risk Management (ISO 14971)

✅ What to include:

Risk Management Plan: Explains how you detect, analyze, assess, control, and check risks.

Risk Analysis: Hazard identification, risk estimation, and risk evaluation.

Risk Control Measures: Risk reduction measures.

Residual Risk Evaluation: Evidence-backed rationale to show acceptability.

Risk Management Report: Document to prove that your device’s residual risks are acceptable.

✅ Why it matters:

Effective risk management is the solution for proving your device is safe enough for patients’ use in normal conditions.

✅ Tip: Give transparent traceability between hazards, controls, and testing in your report, with proof that controls work.

4️⃣ Clinical Evaluation and Data

✅ What to give:

Clinical Evaluation Report (CER): EU MDR and MEDDEV 2.7/1 Rev. 4 requirement.

Literature Reviews: Basis for safety and performance statements.

Clinical Investigations: Investigation plans, data, and outcomes if conducted.

Clinical Equivalence Rationale: Compared to similar devices, if relevant.

✅ Why it matters:

Offers objective proof that your device is operating effectively and is safe for use within the clinic.

✅ Tips: Use your CER to collect new PMS data so it is made easily accessible to ensure future compliance and audit readiness.

5️⃣ Verification and Validation Testing

✅ What to include:

Performance Testing: Bench tests that demonstrate functional performance to specification.

Biocompatibility Testing: Patient-contacting material safety tests (ISO 10993).

Sterilization Validation: Sterilization effectiveness proof (ISO 11135/11137).

Shelf Life and Packaging Validation: Demonstrate the device’s integrity for its declared shelf life.

Software Validation: Reports to IEC 62304.

Electrical Safety and EMC Testing: Reports to IEC 60601 and EMC standards.

✅ Why it matters:

These reports demonstrate that your device always complies with safety and performance standards.

✅ Tip: Document significant test results in summary format with complete protocols and complete reports as part of your inspection report.

6️⃣ Instructions for Use (IFU) and Labeling

✅ What to include:

Labeling Content: Product name, UDI, serial/lot numbers, manufacturer, storage conditions, and warnings.

Instructions for Use (IFU): Clear, concise instructions for users and healthcare professionals.

Translation Records: These are necessary for ensuring EU MDR conformity in each target market.

✅ Why it is important:

Labeling provides consumers with the information they need to use your device safely and efficiently, thereby preventing misuse and reducing liability.

✅ Tip: Make sure that your labeling information is consistent with your risk management, clinical investigation, and design information for your device.

7️⃣ Post-Market Surveillance (PMS) and Vigilance Procedures

✅ What to include:

PMS Plan: This section describes how you systematically collect and evaluate information after the product has been marketed.

PMS Reports and PSUR: According to the EU MDR, periodic reporting refers to the surveillance of device performance.

Vigilance Reporting Procedures: Timely reporting of serious incidents and FSCA.

Complaint Handling Procedures: CAPA and risk control alignment.

Why it matters:

PMS maintains your device through safety and performance claims, enabling proactive risk avoidance.

✅ Practice tip: Align PMS processes with your QMS and make information available for audit review.

8️⃣ Declaration of Conformity (DoC)

✅ What to include:

The device’s identification details should be included.

Regulations and standards that have to be utilized for conformity testing.

The manufacturer’s company information should be proThe manufacturer’s company information was provided.

Your management staff must authorize and sign off on the document.

✅ Why it is important

A DoC is a requirement for a CE mark by law, ensuring your compliance adherence.

✅ Practical tips and advice: Always keep your DoC by the standards used in your technical file.

???? Maintaining Your Technical Documentation Up-to-Date and Your Documentation in Order

Document Control: Documentation is controlled through versioning and is readily available.

Regular Updates: Update your technical file in due course following design revision, clinical revision, or new PMS results.

Internal Reviews: Internal audits were conducted regularly to find and close the gaps.

Digital Systems: Utilize eQMS/DMS to obtain efficiently updated and searchable audits.

⚠️ Errors Typically Committed to Steer Clear of

❌ Poor or unorganized documentation.

❌The traceability of validation, design output, and risk management fails to meet expectations.

❌ Clinical or labeling data is outdated and being used.

❌ Up-to-date PMS data is not being incorporated.

???? Excellent World-Class Technical Documentation Practices

✅ Plan your technical documentation—not after development.

✅ Maintain consistency and traceability of quality in all documentation.

✅ Train employees regularly on regulatory updates and documentation.

✅ Automating documentation to ease the process of audit preparation.

✅ Systematically apply PMS findings to present permanent compliance proof.

???? Real-Life Scenario

A wearable biosensor business preparing for CE marking:

Structured its Technical File based on EU MDR Annex II.

Set the traceability of user needs, risk reduction, and test reports in place.

Added PMS results to its CER for solid proof of compliance.

We have integrated digital platforms to generate documents efficiently and prepare for audits.

Outcome: Passed its Notified Body audit with zero non-conformities and went live in the EU on time.

First-Class Technical Documentation Advantage

✅ Fewer agonizing audits and quicker regulatory clearances.

✅ Operating excellence in quality management.

✅ Greater patient safety and market confidence.

✅ Expandable systems facilitate international expansion.